BMW 7 Series: Removing And Installing/Replacing Left Inlet Camshaft (N63)

Necessary preliminary work

(cylinder bank 5 to 8)

IMPORTANT: The intake camshaft must first be rotated in such a way that the camshaft is free from tension when the bearing caps are released (risk of damage).

- Remove LEFT CYLINDER HEAD COVER.

- Check TIMING.

- Remove LEFT INLET ADJUSTMENT UNIT.

IMPORTANT: No cam on the inlet camshaft is permitted to press directly onto a roller cam follower.

With cylinder no. 1 at 150º before firing TDC there is no piston in the TDC position.

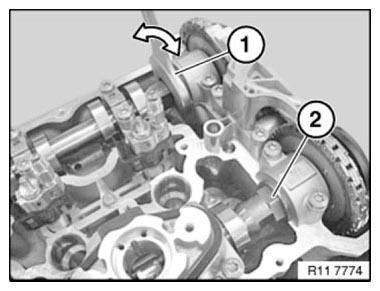

Rotate left inlet camshaft at dihedron with a fork wrench (1) into a suitable position.

Fig. 248: Rotating Left Inlet Camshaft At Dihedron With Fork Wrench

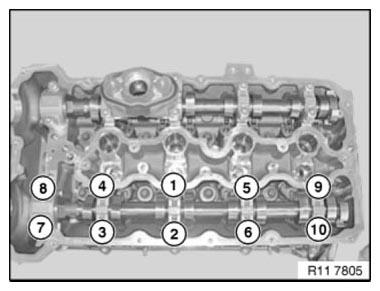

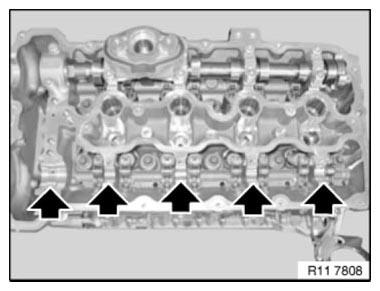

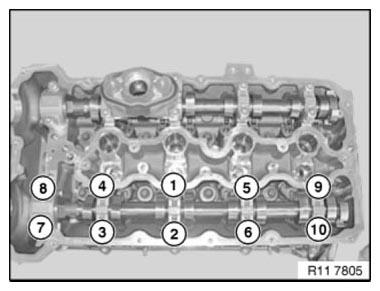

Release bolts of camshaft bearings in sequence (10 to 1) in 1/2 turns.

Set down all bearing caps in a tidy and orderly fashion on special tool 11 4 480.

Intake camshaft

Fig. 249: Identifying Camshaft Bearings Bolts Releasing Sequence

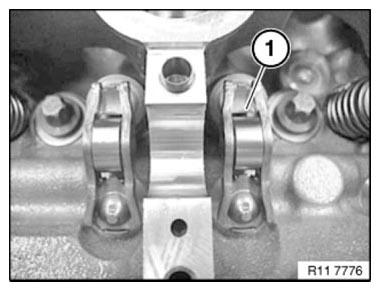

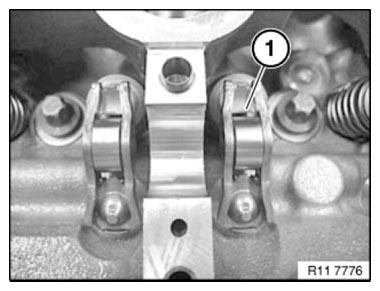

IMPORTANT: Used rocker arms (1) may only be reused in the same position.

NOTE: Rocker arms (1) are freely accessible after inlet camshaft has been removed.

Do "not" remove rocker arm (1) on intake side.

Fig. 250: Identifying Rocker Arm

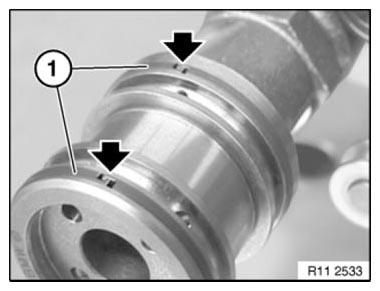

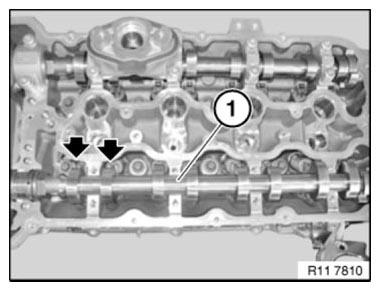

IMPORTANT: Plain compression rings (1) can easily break.

If necessary, replace plain compression rings (1).

Press compression ring (1) on one side into groove, pull up on other side and remove catch.

Carefully pull compression ring (1) apart and remove towards front.

Fig. 251: Locating Compression Ring End

Ends of compression rings (1) point upwards.

Make sure compression rings (1) are engaged at ends.

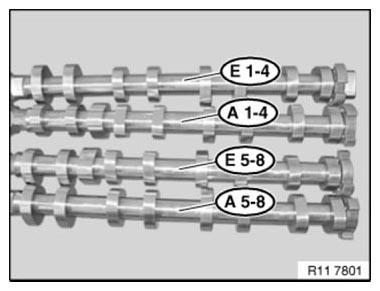

NOTE: The intake camshaft of cylinder bank 5 to 8 is marked with "E 5-8".

Fig. 252: Identifying Camshaft Of Cylinder Bank Mark

IMPORTANT: Rocker arms (1) slip slightly when inlet camshaft is fitted.

Make sure rocker arms (1) are secured as illustrated on hydraulic valve clearance compensating elements and on valves.

Align all rocker arms (1) straight.

Fig. 253: Identifying Rocker Arm

Coat all bearing positions with engine oil.

Insert intake camshaft.

Fig. 254: Locating Bearing Positions

Insert inlet camshaft (1) so that cams point to side at cylinder 5 as shown in picture.

Fig. 255: Positioning Inlet Camshaft So That Cams Point To Side At Cylinder 5

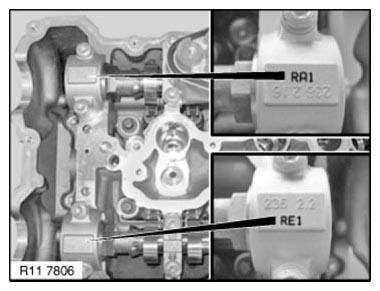

IMPORTANT: Do not mix up the bearing caps of cylinders 1 to 4 and 5 to 8.

All bearing caps are coded and can only be installed in one position.

All bearing caps are marked:

L= Cylinders 1 - 4.

R= Cylinders 5 - 8.

E= Intake side

A= Exhaust side

1= designation from 1 to 5

Fig. 256: Identifying Bearing Caps Mark

Insert all bolts.

Tighten down bolts in sequence (1 to 10) in 1/2 turns.

Tightening torque: 11 31 6AZ.

Tightening torque: 11 31 7AZ.

Fig. 257: Identifying Camshaft Bearings Bolts Tightening Sequence

Install INLET ADJUSTMENT UNITS.

Adjust VALVE TIMING.

Assemble engine.