BMW 7 Series: Replacing Front Left Door Post (Front Side Panel Removed)

Procedure OBSERVE repair stage 3! Read contents of BODY, GENERAL.

Spot-weld bonding is used on this vehicle. Observe specific procedure See SPOT-WELD BONDING STEEL PARTS.

Place vehicle on straightening bench.

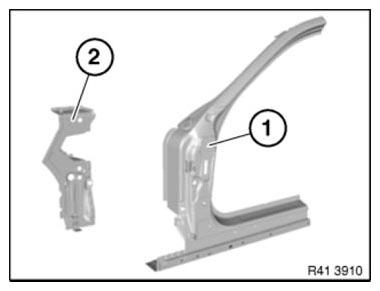

Following new body parts are required:

- A-pillar, outer

- Connection, side frame

- Shaped part, carrier support, wheel arch, front (not shown)

- Shaped part, carrier support, wheel arch (not shown)

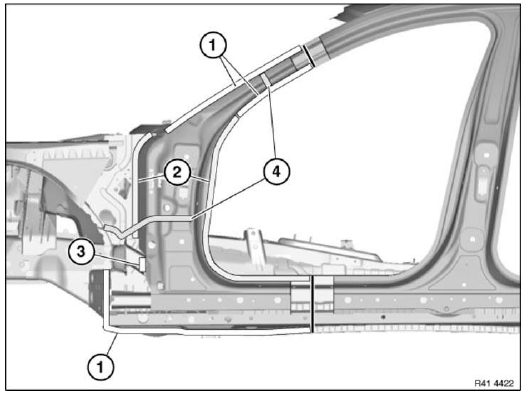

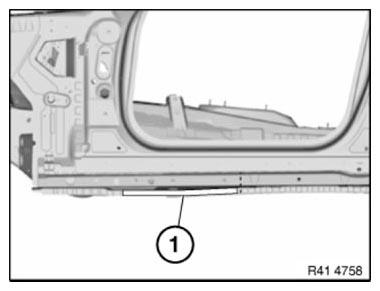

Fig. 312: Identifying Connection, Side Frame And A-Pillar, Outer

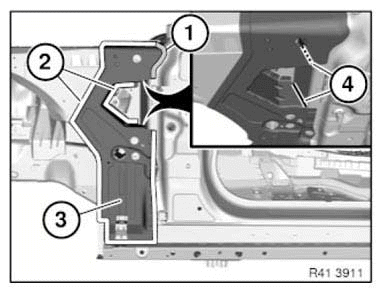

Open spot-welded adhesive joint in area (1).

Open welded connections in areas (2).

Roughly cut side frame connection along lines (4).

Remove side frame connection (3).

Installation note:

MAG-weld new part in areas (4).

To do so, apply 10 mm long fillet welds at spacing of 15 mm.

Fig. 313: Identifying Spot-Welded Adhesive Joints Area And Side Frame

Connection

Fig. 314: Identifying Welded Connections Areas And Sheet Sections

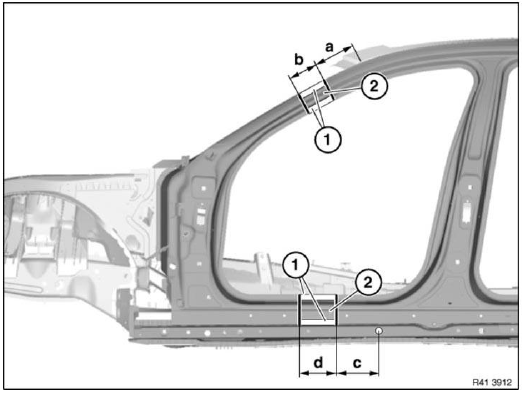

Mark severance cuts in accordance with specified dimensions and cut.

IMPORTANT: Cut outer panel only for following severance cuts.

Dimension a = 200 mm from roof edge.

Dimension b = 100 mm below severance cut a.

Dimension c = approx. 165 mm before center of hole diameter 15 mm.

Dimension d = 140 mm before severance cut c.

Open welded connections in areas (1).

Remove sheet sections (2).

Installation note: Cut-out metal sections (2) are required again for sealing.

Weld in REINFORCEMENT PLATES at all severance cuts.

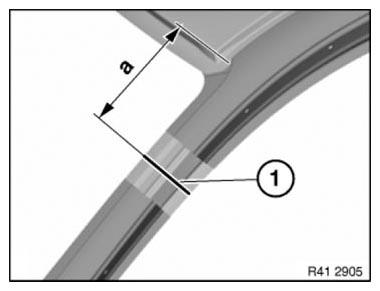

IMPORTANT: For following severance cut, do not damage slide/tilt sunroof water drain hose.

Cut outer panel only.

Mark severance cut (1) in accordance with specified dimension and cut.

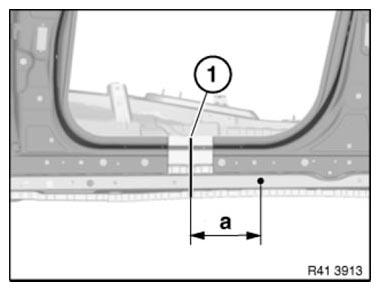

Dimension a = approx. 250 mm from roof edge.

Fig. 315: Identifying Roof Edge Cutting Dimension

Mark severance cut (1) in accordance with specified dimension and cut.

IMPORTANT: Cut outer panel only.

Dimension a = approx. 235 mm before center of 15 mm dia. hole.

Fig. 316: Identifying Outer Panel Cutting Dimension

Fig. 317: Identifying Bonded Connection Area, Cavity Sealing And Welded

Connections Areas

Open welded connections in areas (1).

Open spot-welded adhesive joints in areas (2).

Open bonded connection in area (3).

Installation note: Replace bonded connection in area (3) with MAG weld seam.

Apply sealant to cavity sealing (4).

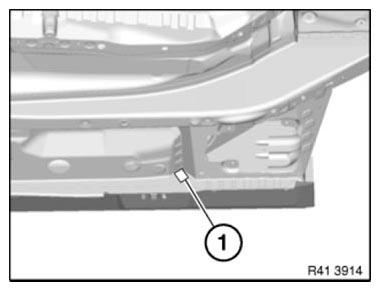

View from below.

Open welded connection (1).

Fig. 318: Identifying Welded Connection

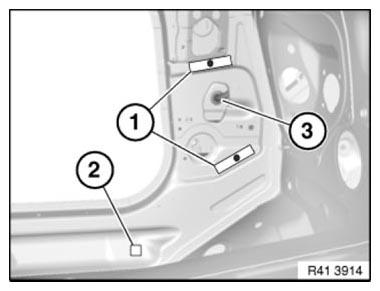

View from inside.

Open spot-welded adhesive joint (1 welding spot in each case) in areas (1).

Open welded connection (2).

Feed out sliding sunroof water drain hose (3) and door post.

Installation note: Prepare body in areas (1) for plug welding.

Fig. 319: Identifying Sunroof Water Drain Hose, Spot-Welded Adhesive Joint

Areas And Welded

Connection

Installation note: Apply repair welding spots in area (1) to existing welding spots on new part/vehicle. This is necessary because the adhesive between the spot flanges acts as an insulator.

Fig. 320: Identifying Welding Spots Area

Installation note:

Mark new part in accordance with severance cuts above and cut.

Adjust new part to fit with alignment bracket or universal mount.

Make sure water drain hose is correctly fitted.