BMW 7 Series: Removing And Installing/Replacing Feed And Return Lines For Engine Oil Cooler (N63)

WARNING: Risk of scalding! Only perform this repair work after engine has cooled down.

IMPORTANT: Wear protective gloves and safety goggles.

IMPORTANT: Adhere to conditions of absolute cleanliness when performing repair work on the engine oil circuit.

When removing engine oil pipes and engine oil cooler, seal off all openings with suitable plugs.

To avoid engine damage, do not allow any dirt particles to get into the engine oil circuit.

Recycling

Engine oil escapes when the engine oil pipe is released.

Catch and dispose of emerging engine oil.

Observe country-specific waste disposal regulations.

Necessary preliminary work

- Lower FRONT AXLE SUPPORT.

- Remove WHEEL ARCH PANEL front section on right.

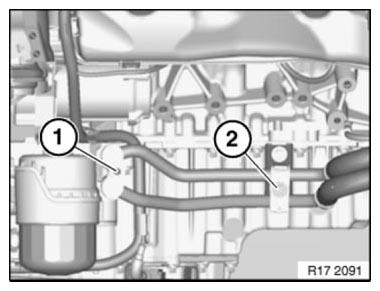

Release screw (1).

Tightening torque 17 22 4AZ.

Release screw (2).

Tightening torque 17 22 5AZ.

Remove engine oil pipes from oil filter control housing and oil sump.

Catch and dispose of emerging oil.

Fig. 49: Identifying Engine Oil Pipes Mounting Screws

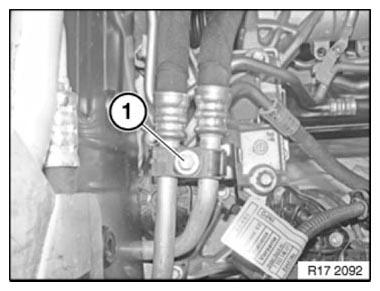

Installation note: Replace all sealing rings of engine oil pipes! Release screw (1).

Tightening torque 17 22 6AZ

Fig. 50: Identifying Engine Oil Pipes Mounting Screw

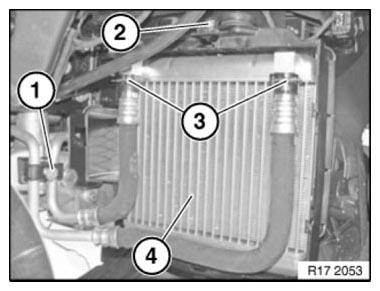

Release screw (1).

Tightening torque 17 22 6AZ.

Unlock engine oil pipes (3) and detach from engine oil cooler (4).

Feed out engine oil pipes (3) and remove.

Catch and dispose of emerging oil.

Fig. 51: Identifying Engine Oil Cooler With Engine Oil Pipes And Mounting

Screw

NOTE: After completion of repair work, check engine oil level. Refill if necessary.

Check engine oil pipes for tightness.

REMOVING AND INSTALLING/REPLACING INTERCOOLER EXPANSION TANK (N63)

IMPORTANT: Danger of scalding! Only perform this work after engine has cooled down.

Necessary preliminary tasks

- Remove ACOUSTIC COVER

- Drain coolant for intercooler

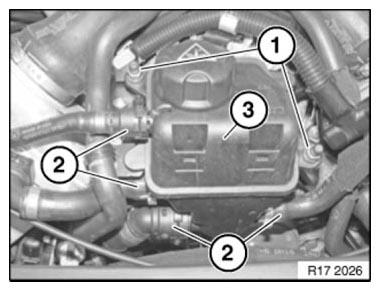

Release screws (1).

Tightening torque 17 10 7AZ.

Release coolant hoses (2) from expansion tank (3) and detach.

Installation: Replace faulty clamps.

Remove expansion tank (3).

Fig. 52: Identifying Intercooler Expansion Tank With Coolant Hoses And

Mounting Screws

Assemble engine.

After completing work, fill intercooler with coolant.

Vent COOLING SYSTEM for intercooler.

Check cooling system for intercooler for leaks.