BMW 7 Series: Checking Camshaft Timing On Left Side (N63)

Notes

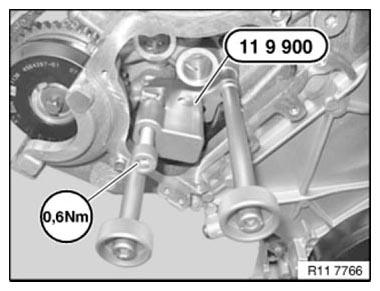

IMPORTANT: The timing can only be checked with special tool 11 9 900.

The timing may be misinterpreted if it is checked without special tool 11 9 900.

Cylinders 5-8:

Necessary preliminary work

- Remove left CYLINDER HEAD COVER

- Remove FAN COWL with electric fan

- Remove BELT PULLEY for air conditioning system

- Remove left CHAIN TENSIONER

Mount special tool 11 9 900 at position of chain tensioner.

Preload hexagon socket screw with special tool 00 9 250 to 0.6 Nm.

NOTE: Graphic corresponds to cylinders 1-4.

Fig. 212: Preloading Hexagon Socket Screw With Special Tool 00 9 250 To 0.6

Nm

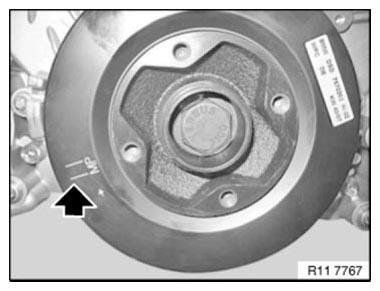

NOTE: Marking (MP = Mounting Position) is important for installing special tool 11 8 570.

MP = 150º before cylinder no. 1 firing TDC position

Fig. 213: Identifying Mounting Position Of Special Tool 11 8 570

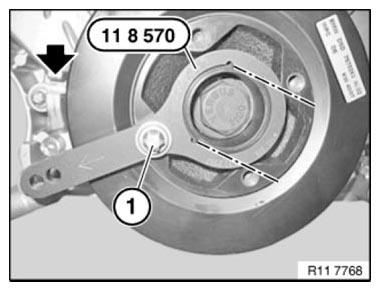

Position special tool 11 8 570 with dihedron on vibration damper in such a way that it can be secured with bolt (1) at the MP marking.

NOTE: Setting groove on crankcase, see arrow.

Fig. 214: Positioning Special Tool 11 8 570 With Dihedron On Vibration Damper

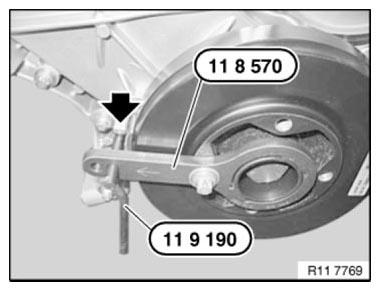

Crank engine at central bolt.

Secure vibration damper with special tools 11 8 570 and 11 9 190 at 150º before cylinder no. 1 firing TDC position.

Fig. 215: Securing Vibration Damper With Special Tool 11 9 190

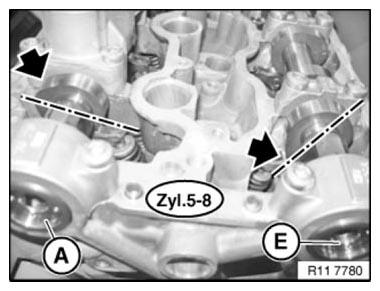

With cylinder no. 1 at 150º before firing TDC position, cams on exhaust camshaft (A) at cylinder no. 5 point at an angle to the left.

Cams on inlet camshaft (E) point at an angle downwards.

NOTE: For purposes of clarity, the graphic shows the inlet and exhaust adjustment units removed.

Fig. 216: Identifying Cams On Inlet Camshaft Point At An Angle Downwards

IMPORTANT: When the engine is shut down, the inlet and exhaust adjustment units are normally locked in their initial position.

The situation may arise in some individual cases where this initial position is not reached and the camshaft can continue to be rotated in the adjustment range of the camshaft adjuster.

In order to avoid incorrect timing adjustment, it is essential to check the locking of the camshaft adjuster and if necessary perform locking by rotating the camshafts.

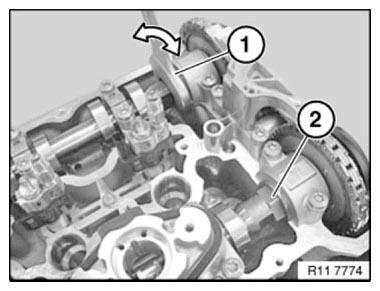

Checking locking of intake and exhaust camshaft adjusters in initial setting: Gripping hexagon head (2) of camshafts with a fork wrench (1), carefully try to rotate camshafts against direction of rotation.

The intake and exhaust camshaft adjusters are locked in the initial setting when the camshafts are non-positively connected to the adjusters.

Fig. 217: Gripping Hexagon Head Of Camshafts With Fork Wrench

IMPORTANT: If the intake or exhaust camshaft adjusters of the camshafts "cannot" be locked as described, the adjuster is faulty and must be replaced.

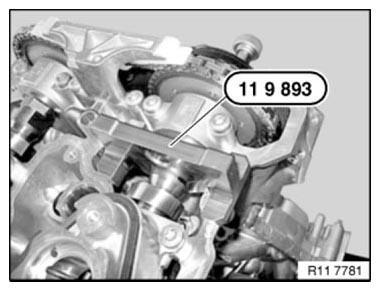

Place special tool 11 9 893 on the exhaust camshaft and check timing adjustment.

NOTE: Timing is correctly adjusted when special tool 11 9 893 rests without a gap on cylinder head.

Fig. 218: Identifying Special Tool 11 9 893 On Exhaust Camshaft

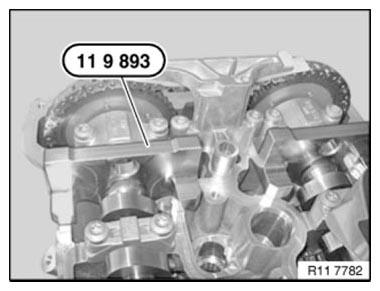

Fit special tool 11 9 893 on intake camshaft and check timing adjustment.

NOTE: Timing is correctly adjusted when special tool 11 9 893 rests without a gap on cylinder head.

If necessary, adjust camshaft TIMING on left side.

Fig. 219: Identifying Special Tool 11 9 893 On Intake Camshaft

Remove all special tools.

Assemble engine.